& nbsp; High speed fans and high-pressure fans are two different types of fan equipment used in industry, with differences in wind pressure range, working mode, and structural dimensions. The following is a specific analysis:

& nbsp; Wind pressure range

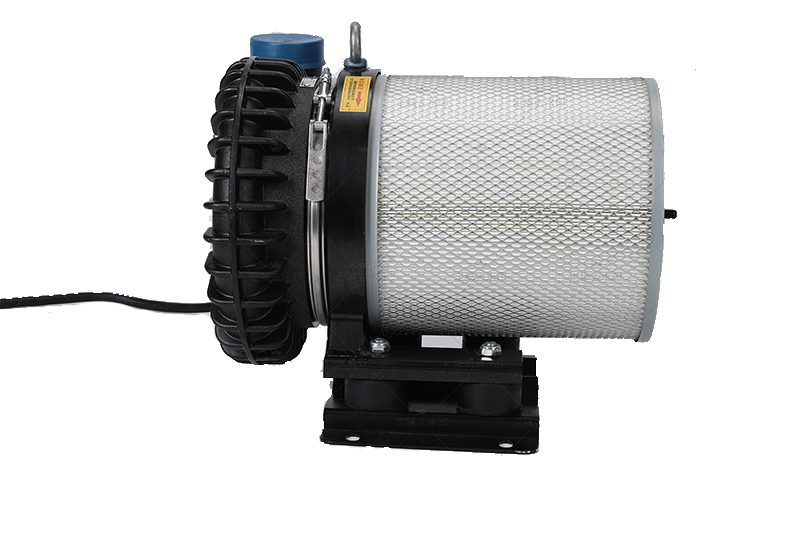

& nbsp; High speed blower: High speed blowers typically have high rotational speeds, with wind pressures ranging from 50-290mbar and air volumes of 85-6000 cubic meters per hour. Under normal circumstances, the rotational speed can reach up to 18000-21000 revolutions per minute. The design of this fan enables it to generate a large amount of airflow and has an efficiency of over 95%. Smed's latest developed permanent magnet fan can reach a maximum speed of 28000 revolutions per minute, achieving higher air volume and lower energy consumption.

& nbsp; High pressure fan: The pressure range of high-pressure fans is 30kPa to 200kPa. Compared to high-speed fans, their focus is on providing higher gas pressure rather than air volume. High pressure fans are suitable for fields such as pressurized circulation, material conveying, and forced ventilation.

& nbsp; operation mode

& nbsp; High speed fan: The impeller design resembles an obtuse flattened cone, with blades in a spiral shape. When the impeller rotates, air is trapped by the blades; Catch '; And it is thrown out under tremendous centrifugal force, achieving air compression and generating large air volume, so it is also called a centrifugal blower.

& nbsp; High pressure fan: Using the centrifugal force generated by the rotation of the impeller, it drives the gas to move forward and outward, forming a spiral motion, thereby accelerating the rotation of the air and increasing the gas pressure.

& nbsp; structure size

& nbsp; High speed fan: with a small and compact structure, the impeller size is small but the speed is high, and the inlet diameter is also small.

& nbsp; High pressure fan: The overall size is relatively large, especially the front pump body is larger to meet the demand for higher pressure. The impeller may be larger or designed with special angles to increase pressure.

& nbsp; performance parameter

& nbsp; High speed fan: characterized by low noise, low maintenance, reliable operation, and durability. In addition, high-efficiency motors (such as ABB motors) with high protection levels are used, and the main components are made of high-strength materials.

& nbsp; High pressure fan: Its design focuses on increasing gas pressure, resulting in higher power, higher efficiency, and faster impeller speed. Structurally more robust to withstand long-term operation in high-pressure environments.

& nbsp; application area

& nbsp; High speed fan: suitable for occasions that require high air volume, high efficiency, and low noise, such as rapid ventilation and cooling in some industrial processes.

& nbsp; High pressure fan: commonly used in fields such as pressurized circulation, material conveying, and forced ventilation, with a wider range of applications. For example, used in factories, mines, tunnels, cooling towers, and other places that require high pressure.

& nbsp; When choosing a fan, the following factors need to be considered:

& nbsp; Determine the required wind pressure and air volume, and select the appropriate fan type based on specific application requirements.

& nbsp; Considering noise control requirements, if a quiet environment is required, priority should be given to high-speed fans with low-noise designs.

& nbsp; Pay attention to energy efficiency ratio, choose high-efficiency motors and suitable speed control devices to optimize operating costs.

& nbsp; Evaluate the installation space and equipment size limitations to ensure that the selected fan can adapt to the on-site environment.

& nbsp; Regularly maintain and check the condition of key components such as impellers and casings to ensure the long-term stable operation of the fan.

& nbsp; In summary, high-speed fans and high-pressure fans each have their own advantages and characteristics. High speed fans are adept at applications with high air volume, high efficiency, and low noise; High pressure fans are more suitable for industrial environments and applications that require higher pressure. The selection of which type of fan to use should be based on actual usage needs and working conditions. Compared with high-pressure fans, our company's super high-speed fans and permanent magnet high-speed fans have more than twice the air volume within the same power. Each fan can save tens of thousands of costs per month. We have transformed many enterprises into our energy-saving fans, which have received unanimous praise from customers and provide strong support for energy-saving, consumption reducing and green development of enterprises.